Analysis of the "Energy Fusion Core" PCB Design: Components and Zones

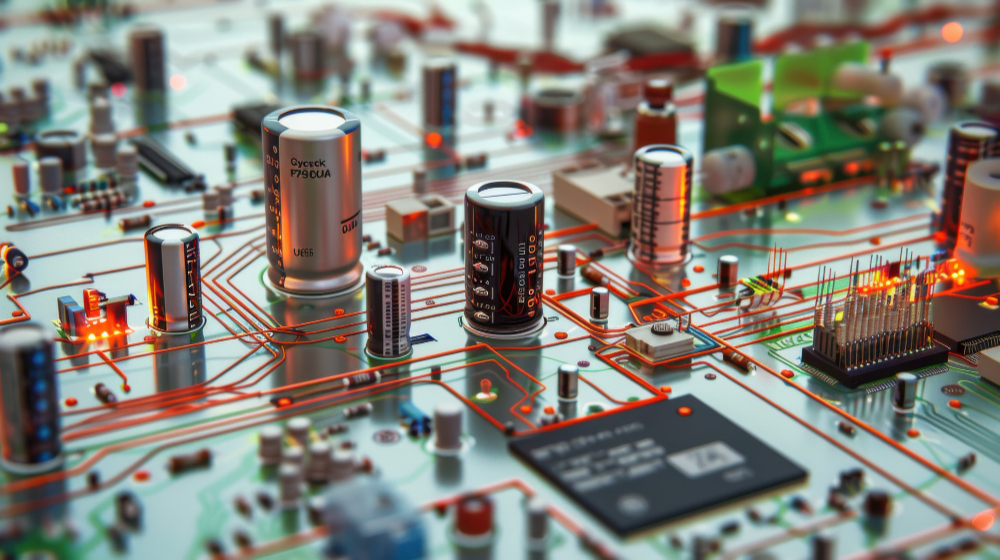

The conceptual PCB layout for the “Energy Fusion Core” (EFC) system is organized into distinct functional zones, each containing key components responsible for specific tasks within the overall power conversion and distribution chain. Understanding the assumed functions of these components, based on their labels and placement, is essential for analyzing the system’s intended operation. Table 1 provides a summary of these key components and their hypothesized roles.

Table 1: Overview of Key PCB Components and Their Assumed Functions

| PCB Label | Bengali Label (Approx. Translation) | Assumed Function | Key Technologies Involved | Relevant Research |

| Power Input & Conditioning Zone | ||||

| J_GRID | Grid In (AC) | AC power input connector from the utility grid. | High-voltage AC connector. | |

| U1_GRID_PROC | Grid Processing | AC-DC rectification of grid power, Power Factor Correction (PFC), voltage stabilization, and protection. | Active rectifier (e.g., Vienna, bridgeless boost), PFC controller, EMI filtering, surge protection. | |

| J_SOLAR | Solar In (DC) | DC power input connector from solar PV panels. | DC connector. | |

| U2_SOLAR_MPP | Solar MPPT | Maximum Power Point Tracking to optimize power extraction and DC-DC conversion to match EFC_X1 input voltage. | MPPT algorithms (e.g., P&O, Incremental Conductance), DC-DC converter (boost, buck-boost). | |

| J_TURBINE | Turbine In (DC) | DC power input connector from a turbine generator (e.g., wind, micro-hydro) after rectification. | DC connector. | |

| U3_TURB_PROC | Turbine Processing | Power conditioning for turbine input: voltage regulation, stabilization, DC-DC conversion. If turbine output is AC, this includes rectification. | Rectifier (if AC input), DC-DC converter (buck, boost, buck-boost), filtering, voltage regulation. | |

| Central “Energy Fusion Core” | ||||

| EFC_X1 | Central “Energy Fusion Core” | Central energy management unit: aggregates power from inputs, dynamic power flow control, DC bus voltage synthesis/stabilization. Labeled “Dynamic Synthesizer.” | Multi-input Multi-output (MIMO) DC-DC converter, intelligent DC bus management system, advanced control algorithms. | |

| EV Charge Control & Distribution Zone | ||||

| DC Bus | Direct Charging DC Bus (+VCC / GND) | High-capacity DC distribution bus from EFC_X1 to EV controllers. | Heavy copper traces, busbar design, high-power DC distribution. | |

| U_EV_CTRL1/2/3 | EV Controller 1/2/3 | Manages charging for an EV dock: EV communication (ISO 15118, SAE J1772), controls power delivery (voltage/current) through a DC-DC stage. | Microcontroller, Communication IC (PLC, CAN), DC-DC converter (buck, resonant), gate drivers. | |

| Charging Dock Output Interface | ||||

| J_DOCK1/2/3_OUT | Dock 1/2/3 Output | Physical connector for EV charging (e.g., CCS, CHAdeMO, NACS). | Standardized EV charging connectors. | |

| Central Control & Monitoring | ||||

| U_MCU_SYS_CTRL | Central Control & Monitoring | Overall system supervisor: energy management, control of EFC_X1 and EV_CTRLx, network communication (OCPP), fault detection, safety. | High-performance MCU/MPU, Real-Time Operating System (RTOS), communication interfaces (Ethernet, CAN), sensor inputs. |

Detailed Description of Zones and Components:

- “Power Input & Conditioning Zone”: This zone is responsible for receiving energy from three distinct sources and conditioning it for use by the central EFC_X1.

- J_GRID and U1_GRID_PROC: Grid input (J_GRID) is AC, requiring AC-DC conversion by U1_GRID_PROC. This “Grid Processing” unit is critical. Beyond simple rectification, it must incorporate Power Factor Correction (PFC) to ensure high efficiency and low harmonic distortion, conforming to grid standards. Modern EV chargers frequently employ active PFC circuits, such as Vienna rectifiers or interleaved boost converters, to achieve near-unity power factor for this purpose. This unit would also contain protective components like fuses and surge arresters.

- J_SOLAR and U2_SOLAR_MPPT: Solar power, being inherently DC, is supplied via J_SOLAR. The U2_SOLAR_MPPT unit is vital for maximizing energy harvest from photovoltaic panels. It uses a DC-DC converter controlled by a Maximum Power Point Tracking algorithm, which continuously adjusts the converter’s operating point to match the solar panel’s peak power output under varying sunlight and temperature conditions.

- J_TURBINE and U3_TURB_PROC: The turbine input (J_TURBINE), which is DC, requires “Turbine Processing” by U3_TURB_PROC. If the turbine (e.g., wind or micro-hydro) generates AC, this unit would first rectify it. Subsequently, DC-DC conversion would regulate and stabilize the voltage to meet the EFC_X1’s input specifications. Power from sources like wind turbines can be highly variable, necessitating robust power conditioning to ensure a stable DC output. For micro-hydro systems, specific conditioning units ensure compatibility with a DC bus.

- “Central ‘Energy Fusion Core’ (EFC_X1)”: This module is depicted as the conceptual heart of the system. Its prominent central location, multiple input connections from the conditioning zones, and outputs to the EV charging distribution zone, coupled with the descriptive text “Energy Fusion Core” and “Dynamic Synthesizer,” strongly suggest a sophisticated energy management unit. It likely functions as either an intelligent common DC bus or a Multi-Input Multi-Output (MIMO) DC-DC converter. Its core functions would include aggregating power from diverse inputs, dynamically managing power flow based on source availability, EV charging demand, and potentially external signals (e.g., grid pricing, demand response commands), and synthesizing a stable, regulated DC bus voltage to supply the EV charging controllers. This is consistent with research into DC-coupled charging hubs and advanced MIPEC-s. For instance, the NREL ECHIP project focuses on such centralized DC hub architectures for high-power charging.

- “EV Charge Control & Distribution Zone”: This zone handles the final stage of power distribution to the EVs.

- U_EV_CTRL1, U_EV_CTRL2, U_EV_CTRL3: Each of these “EV Controllers” is dedicated to managing the charging process for a single EV charging dock. Their responsibilities include establishing communication with the connected EV (using protocols like SAE J1772 for basic signaling and ISO 15118 for higher-level communication) to ascertain battery status, negotiate charging parameters (voltage, current), and control power transfer. These controllers would command a DC-DC power conversion stage (either integrated within the U_EV_CTRL module or as a closely related unit) to deliver the precise voltage and current required by the EV battery.

- “Direct Charging DC Bus (+VCC / GND)”: This is a high-capacity DC bus that distributes conditioned power from the EFC_X1 to the individual EV controllers. The labels “+VCC / GND” indicate a bipolar DC system or a common ground reference. The design of this bus is critical to minimize losses when carrying substantial currents to multiple high-power chargers.

- “Charging Dock Output Interface”:

- J_DOCK1_OUT, J_DOCK2_OUT, J_DOCK3_OUT: These represent the physical connectors (e.g., CCS, CHAdeMO, NACS, depending on regional standards and target vehicles) that provide the actual power and communication interface to the electric vehicles.

- U_MCU_SYS_CTRL (“Central Control & Monitoring”): This Microcontroller Unit (MCU) is depicted as the overall brain of the charging station. Its “Central Control & Monitoring” role implies comprehensive oversight of all system operations. This includes monitoring power inputs from the grid, solar, and turbine sources; controlling the EFC_X1 to achieve optimal power blending and distribution; communicating and coordinating with individual U_EV_CTRLx modules; implementing overall energy management strategies such as dynamic load balancing among the docks and potential peak shaving when integrated with energy storage; handling external communication for remote monitoring, billing, and grid services (e.g., via OCPP); and managing system-wide fault detection and safety protocols. The sophisticated tasks managed by U_MCU_SYS_CTRL are typical of modern Site Energy Management Systems (SEMS) in advanced charging hubs.

The architectural coordination of distributed EV controllers (U_EV_CTRLx) for individual dock management and a central supervisory MCU (U_MCU_SYS_CTRL) points towards a hierarchical control structure. This arrangement offers benefits in terms of modularity and scalability, allowing for potential addition or modification of charging docks without overhauling the central control logic. However, it necessitates robust and high-speed internal communication paths between the U_MCU_SYS_CTRL, EFC_X1, and each U_EV_CTRLx. These internal communication links, while not explicitly detailed as separate components on the simplified PCB, are functionally indispensable for integrated operation. This is analogous to the coordinated control seen between central and distributed units in other complex power electronic systems.

Furthermore, the “Dynamic Synthesizer” annotation associated with EFC_X1 indicates capabilities extending beyond simple power aggregation and DC bus regulation. In the context of power electronics, “synthesis” can imply active shaping of power characteristics. If the EFC_X1, in conjunction with a bidirectional U1_GRID_PROC, is designed with the ability to feed power back to the grid or manage reactive power, it could enable the charging station to provide ancillary services. This would transform the station from a passive load into an active grid participant, a concept gaining traction in smart grid development, especially when combined with local energy storage (though a BESS is not explicitly shown on this PCB, it’s a common component of such energy hub concepts).

Team

Our Driving Force - Our Dedicated Team

The success of “Shead Green Mobility and Renewable Technology OPC” is rooted in the collective efforts of a group of talented, enthusiastic, and dedicated individuals. Each member of our team is experienced in their respective fields and deeply committed to the company’s goals and philosophy. Besides the founder, our team includes technologists, engineers, marketing experts, and skilled managers who are working tirelessly to turn this green mobility revolution into reality.

MD Mohiminul Islam Shead

He is the hero behind "Shead Green Mobility and Renewable Technology private limited company"

Professor Dr. Md. Nurul Amin

Professor Dr. Md. Nurul Amin stands as a pivotal figure and visionary co-founder of Shead Green Mobility and Renewable Technology OPC (SMRT)